INTRODUCTION TO UV COATING

UV coating is a type of coating that uses ultraviolet radiation as the curing method (UV is UltraViolet radiation).

MOST COMMON MISTAKES WHEN APPLYING EPOXY

AUTOMOTIVE COATINGS MARKET

What's the Difference Between Polyurethane, Varnish, Shellac and Lacquer?

NO SELF-HEALING PAINT

INTRODUCTION TO UV COATING

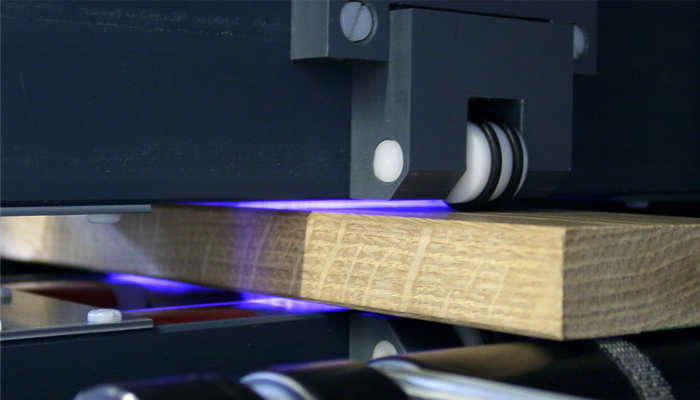

What is UV Coating?

In the industry of wood manufacturing, PU coating is almost indispensable. Also, UV paint is particularly important for wooden floors.

UV coating is a type of coating that uses ultraviolet radiation as the curing method (UV is UltraViolet radiation)

This type of paint has many advantages compared to other paint productions such as PU, NC (one-component primer), AC (two-component topcoat).

Let’s explore the advantages and disadvantages of UV coating.

Advantages, disadvantages, applications, and some guides to use UV coating

Advantages

- Can be used for both injection and rolling methods.

- Quickly cure almost immediately when passing through a UV drying chamber or UV lamp.

- Even coverage.

- High clarity.

- Hard paint film, good scratch resistance (essential for wooden floors).

- Chemical resistant, waterproof, and weather resistant.

- Environmentally friendly

- Can be applied along the industrial chain

Disadvantages

- UV paint is not diluted with solvents and has a high viscosity, so it is mostly used with the rolling method. However, the rolling method is only suitable for flat or slightly curved surfaces such as wooden floors.

- For more diverse surfaces, the spray method by dilution with solvent must be used, but this method is complicated, not effective.

- UV paint requires a UV emitter

- High cost.

Moreover, UV paint can also be used on other surface materials such as marble, metal, phone cases, computers, electronic devices, glass, tiles, etc.

Note

- The chemical components of UV paint cannot cure, so it is easily absorbed through the skin. Hence, avoid direct contact with UV paint and wear a mask when working. If the paint touches your skin, wash immediately with soap within 60 minutes.

- Avoid contact with eyes, mouth, and sensitive skin.

- Avoid looking directly into the UV lamp during the production process

UV coating process

After going through the surface treatment (flat grinding and filling) floorings will be finished with UV coating with the following steps:

Step 1: Wood surface treatment: You use sandpaper to sand the wood surface until it becomes smooth. Increase the sandpaper level to about 380.

Step 2: Wood defect treatment, use liquid wood filler to cover these defects.

Step 3: Primer. This is the first step to create a smooth surface as well as increase the adhesion of the UV paint on the wood surface.

Step 4: Apply topcoat to the wood surface. Depending on the type of wood, we will decide to cover it with how many layers

Step 5: Dry the paint with the UV dryer. Note to wash drying equipment before drying to avoid the situation that the long-lasting paint in the machine melts into the new paint layer, causing damage to the whole painting process.

Step 6: Finish the manufacturing process. The products can be sold on the market.

Depending on the technical requirements of each different product, the UV coating producing lines will be adjusted, as well as depending on the hardness requirements, the manufacturer will decide how much UV coating on those products.

Above we have summarized the basic knowledge about UV coating. Currently, Mega Vietnam provides all kinds of raw materials for the production of UV paint on wooden floors such as Oligomer, Monomer, additives. Contact us to get advice about the production process and technical issues related to this product.

>> Get advice on technology transfer of UV coating production <<

Contact

MEGA VIETNAM

Office address: Floor 2-A2-IA20, Nam Thang Long Urban Area, Pham Van Dong Street,

Dong Ngac Ward, Bac Tu Liem District, Hanoi City, Vietnam

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89 098

Website: megavietnam.vn

Hotline: 1800.577.728 Zalo: 0971.023.523