TWO-COMPONENT METALLIC COATING: BENEFITS AND DRAWBACKS

The definition of the two-component metallic coating is extremely easy to understand: It is the coating applied to metal that includes 2 main components: Paint and Curing agent.

MOST COMMON MISTAKES WHEN APPLYING EPOXY

AUTOMOTIVE COATINGS MARKET

What's the Difference Between Polyurethane, Varnish, Shellac and Lacquer?

NO SELF-HEALING PAINT

ZINC PHOSPHATE AND ITS CORROSION RESISTANCE

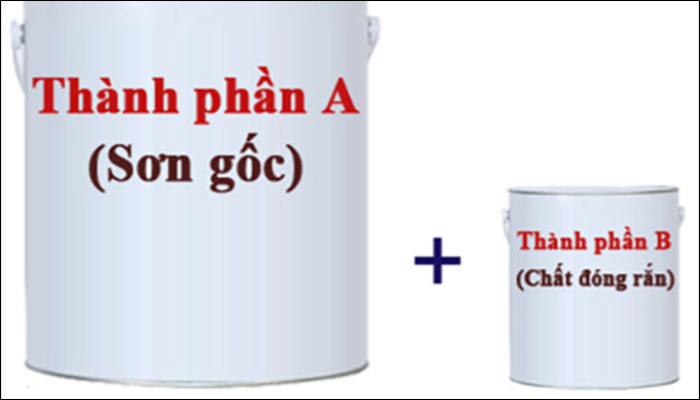

1. Definition

Right from the name, the definition of the two-component metallic coating is extremely easy to understand: It is the coating applied to metal that includes 2 main components: Paint and Curing agent.

- Paint: is acrylic resin or epoxy resin combined with super fine color particles, surfactants, additives, etc to protect and increase the aesthetics of the product.

- Curing agents: When mixed with paint, they will create a durable bonding "network" for the metal surface and promote the role of each component.

The two-component metallic coating can be an epoxy-based two-component metallic oil paint (two-component Epoxy coating) that provides absolute protection for the machine's surface, or a two-component anti-rust Epoxy coating applicable to metal surfaces that get frequent impacts from the external environment.

Two-component metallic coating

2. Advantages and disadvantages of two-component metallic coating:

Two-component metallic paint is widely used in construction, interior, and exterior decoration due to the following advantages:

- High hardness, good heat resistance, good corrosion resistance, and impact resistance

- Anti-oxidation, anti-rust

- Anti-mold, anti-dust, easy to clean

- Good adhesion and high color durability

>>>Get technical advice for the painting process

Besides, the disadvantages of this paint line are:

- Slow painting construction due to the mixing process

- Should be used in 4-6 hours after mixing for the best quality

Two-component metallic coating

3. Application of two-component metallic coating

Despite the high cost compared to single-component paints, the two-component metallic coatings are still be commonly used to protect steel structures from extreme weather due to their advantages.

Hence, manufacturers are constantly improving their quality of and produce new coating products suitable for each type of materials and customers’ requirement:

- Two-component galvanized paint: Suitable for zinc surfaces

- Two-component iron paint: For iron and steel metal surfaces without zinc coating

- Two-components primer: Protect and cover metal surface defects

- Two-component rustproof paint: Protect metal against corrosion and oxidation

>>>Read more: Materials for paint for zinc <<<

Currently, Mega Vietnam Chemical Company has been developing many coating products for the two-component Epoxy paint on metal.

We imported high-standard Acrylic resin and Epoxy resin from Korea, America, Thailand like YD011x75, DOW671x75, AN-5476 along with hardener sets from famous brands such as Aditya Birla Chemicals, Epochem, DOW, etc.

With a trustworthy origin of products and an experienced team, Mega believes to be a reliable partner in coating production.

Contact

MEGA VIETNAM

Office address: Floor 2-A2-IA20, Nam Thang Long Urban Area, Pham Van Dong Street,

Dong Ngac Ward, Bac Tu Liem District, Hanoi City, Vietnam

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89 098

Website: megavietnam.vn

Hotline: 1800.577.728; Zalo: 0971.023.523