UV PAINT - BASIC COMPOSITION OF UV PAINT

UV-Curable material (UV-Curable material) is a paint whose composition differs from popular paints by nature, using only the energy of UV rays to decompose free radicals for free radicals.

MOST COMMON MISTAKES WHEN APPLYING EPOXY

AUTOMOTIVE COATINGS MARKET

What's the Difference Between Polyurethane, Varnish, Shellac and Lacquer?

NO SELF-HEALING PAINT

UV PAINT - BASIC COMPOSITION OF UV PAINT

1. Definition

UV-Curable material (UV-Curable material) is a paint whose composition differs from popular paints by nature, using only the energy of UV rays to decompose free radicals for free radicals. Curing reaction should follow the habit, people call it UV paint. This means that if you use any energy source, just enough intensity to decompose the initiator can harden the paint. Or any chemical reaction that produces free radicals also cures the paint (such as curing reaction of unsaturated polyester).

2. Basic ingredients of UV paint

- Oligomer Acrylate: Epoxy acrylate, Urethane Acrylate, Polyester Acrylate ...

- Monomer: TPGDA, DPGDA, TMPTA, HDDA, IBOMA ...

- PI (optical activator): TPO, 1173, 184 ...

2.1. Oligomer Acrylate

Epoxy acrylate: The most common and basic resin of UV paint because of its properties such as good adhesion, no yellowing, high hardness, good chemical resistance, and many applications for UV coatings for wood.

Urethane Acrylate: The acrylate UV urethane acrylate cured resin has high performance on a wide range of material surfaces. They are used a lot because of their good hardness, elasticity, and curing speed depend on the type of Oligomer. Because of their high strength and flexibility, these resins are often used as resilient floor coatings and as covers for flexible packaging. Other applications include ink, paper, and cardboard.

Acrylate polyesters: Manufactured with a wide range of reactivity and viscosity, mainly used in printing inks, wood, and paper coatings. The resin is very attractive because of its relatively low price and a large number of esters in the molecule allow many changes in the mechanical properties of the coating.

Silicone acrylate: Excellent heat, weather, chemical resistance, good resistance to scratches and abrasion, no gold, excellent transparency, and good electrical insulation properties. This type of UV resin is often used as a protective coating for fiber optics and the coating of electronic components.

>>>Click HERE for free construction consulting<<<

2.2. Monomer

Works as a curing agent, adjusting viscosity, adjusting some properties such as adhesion, film hardness ...

- tripropylene glycol diacrylate (TPGDA) is a colorless or light yellow transparent oily liquid, this product is a multifunctional monomer with low skin irritation, low shrinkage, and high activity. As the reactive diluent used in UV radiation cross-linking, it can become a component of cross-linking polymerization and can provide optical films with flexibility and stability. better.

- Dipropylene glycol diacrylate (DPGDA) code SM 627: Low volatility and viscosity combined with oligomer acrylate for high curing speed.

- Hexanediol diacrylate (HDDA) is a colorless liquid with a high boiling point, low viscosity, water resistance, weather resistance, good dilution, and high durability.

- Trimethylolpropane triacrylate (TMPTA) is a colorless or light yellow transparent liquid with high cross-linking density widely used in light curing ink, surface coating, enhanced abrasion resistance, adhesion, and high gloss.

- Diethylene glycol propylene phthalate (PDDA): is a multifunctional monomer with a high boiling point, low volatility, widely used for light curing ink, coating, photosensitive plastic sheets, etc.

- Neopentyl glycol diacrylate (NPGDA) is a colorless liquid with strong dilution function and wear resistance, good scratch resistance is used for curing coatings of sputtering, inks, adhesives, and photosensitive plastic sheets.

2.3. Photointinator

Photointinator (PI) called optical activator is a molecule or combination of molecules that, when exposed to ultraviolet light, begins to polymerize with a fast rate of light-absorbing Photoinitiators UV and convert light energy into chemical energy.

Consists of main types:

- 1173 powder form accelerates the surface drying process

- Liquid TPO has low viscosity, which helps to accelerate the drying process

3. Application

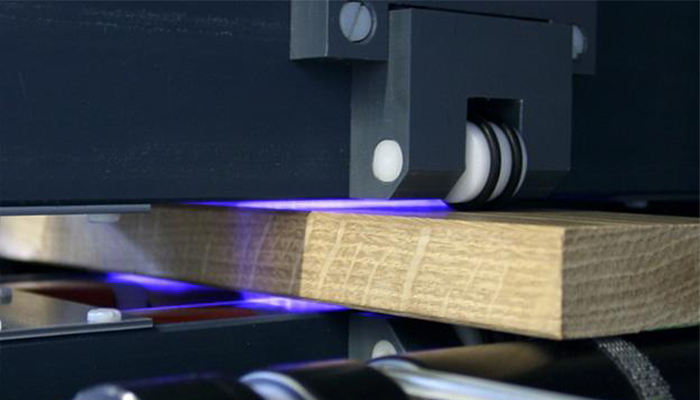

UV paint is most commonly used for wood, especially industrial flooring.

Drying with UV rays

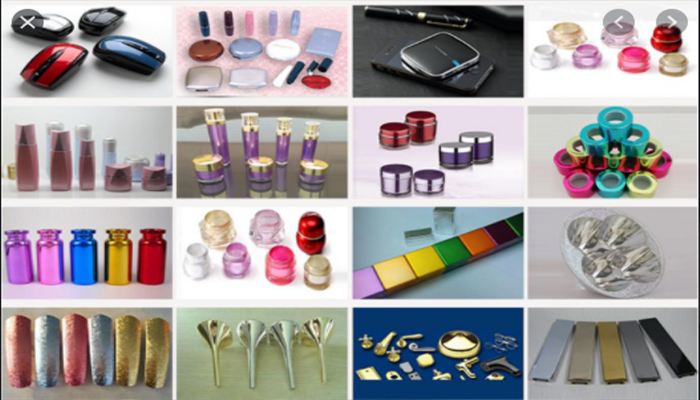

For plastic and metal surfaces

Application of UV paint

Currently Mega Vietnam Chemical Company we are providing materials and additives for the production of UV paint,

>>>Click HERE for more paint chemicals<<<

Contact

MEGA VIETNAM

Office address: Floor 2-A2-IA20, Nam Thang Long Urban Area, Pham Van Dong Street,

Dong Ngac Ward, Bac Tu Liem District, Hanoi City, Vietnam

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89 098

Website: megavietnam.vn

Hotline: 1800.577.728 Zalo: 0971.023.523