INTRODUCTION OF EPOXY SELF LEVELING

Epoxy Self Leveling paint is a 2-component epoxy coating, consisting of coating and curing ingredients, no solvents, operating on the principle of surface balance.

MOST COMMON MISTAKES WHEN APPLYING EPOXY

AUTOMOTIVE COATINGS MARKET

What's the Difference Between Polyurethane, Varnish, Shellac and Lacquer?

NO SELF-HEALING PAINT

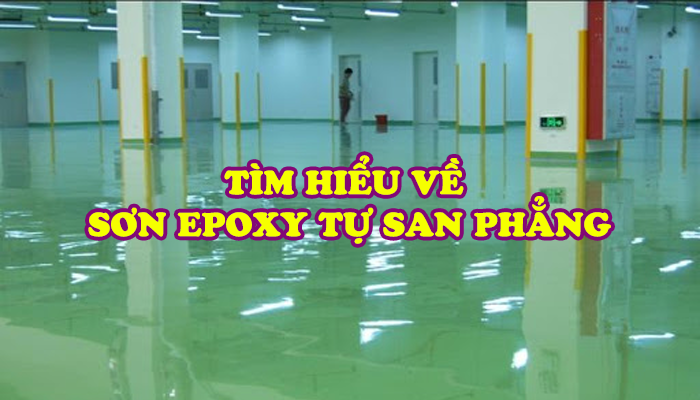

INTRODUCTION TO EPOXY SELF-LEVELING PAINT

1. Definition

Epoxy Self Leveling paint is a 2-component epoxy coating, consisting of coating and curing ingredients, no solvents, operating on the principle of surface balance. If the coating thickness is more than 3 mm, it will conceal the defects of the concrete floor, when pouring the epoxy paint onto the floor surface, this paint will flow evenly to create a glossy, absorbent paint film with a good aesthetic.

Self-leveling epoxy paint is a two-component epoxy paint series, which can be called self-balancing epoxy paint, self-leveling paint, or self-flowing epoxy paint can be painted with many different thicknesses.

Self-leveling epoxy paint is only used for concrete floors, tile floors, wood. It can self-balance the surface when mixing 2 components.

2. Advantages

- High self-leveling ability

- Waterproof, oil resistance, and water resistance

- High load capacity, corrosion resistance

- Good anti-slip ability

- For some famous paint companies Sika, Jotun, KCC, Chokwang, the self-leveling epoxy paint also meets the requirements of GMP, WHO, GPS, GPL ...

>>>Click HERE for free construction consulting<<<

Self-leveling epoxy paint

3. Applications

- Pharmaceutical and food factory floors

- Building basements, parking lots, car garages

- Factory

- Office floor

- The floors require high aesthetics, load capacity, abrasion, and smooth surfaces

4. Self-leveling epoxy floor coating process for the workshop floor

The steps of self-leveling epoxy floor coating are the same as those of 3-coat coating, except for self-leveling coating. For self-leveling floor paint, the workers must be highly skilled, have applied this coating many times because if it has not been done or done a little, the surface is easy to rough, when using semi-serrated scissors to pull. The paint can easily cause drag marks to deteriorate the surface, the surface is thin, each application team must be at least 5 people in which: one person pulls the paint, one uses the spiked roller to break the air bubbles, one pours paint, one applies paint, one tests the surface.

Some notes when applying self-leveling epoxy floor paint:

- Not use solvent, otherwise, it will cause roughness and wrinkling of the epoxy coating surface

- The paint mixing ratio must be exactly as given by the manufacturer.

- Use a paint mixer to the right machine and the rate of rotation per minute, mixing time is at least 10 minutes

- Do not mix paint too much that easily cause curing, must rely on the number of construction workers to mix

- Must know the appropriate construction zoning if not easy to cause the connection between 2 application times and color difference.

- The surface of a weak concrete surface can easily peel off when painted, so for these kinds of floors, it is necessary to treat it with epoxy mortar before applying a self-leveling epoxy coating.

Currently, Mega Vietnam Chemical has been developing many material sets for this Epoxy paint. Especially plastic products of Kukdo (Korea), Kumho (Korea), Epotec (Thailand). With a curing set imported directly from famous brands in the world and a team of experienced technicians, Mega is always a reliable partner and accompanies you to success.

Contact

MEGA VIETNAM

Office address: Floor 2-A2-IA20, Nam Thang Long Urban Area, Pham Van Dong Street,

Dong Ngac Ward, Bac Tu Liem District, Hanoi City, Vietnam

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89 098

Website: megavietnam.vn

Hotline: 1800.577.728 Zalo: 0971.023.523