Chế biến và phân loại cao su thiên nhiên

Ảnh: Minh họa

Ảnh: Minh họa

>>> Nhận tư vấn thi công sản phẩm hoàn toàn miễn phí <<<< />pan>

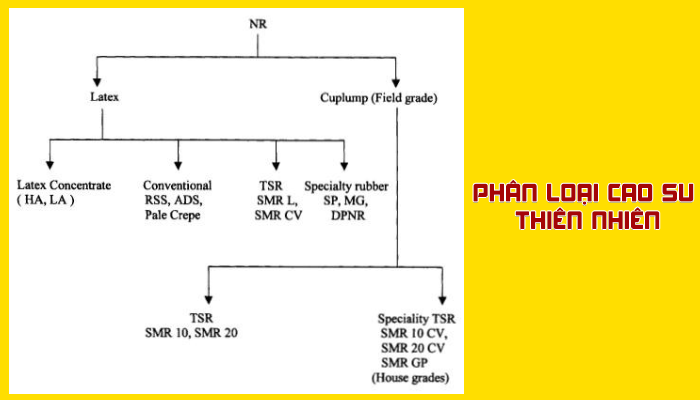

Cao su thu được từ cây cao su chủ yếu dưới dạng latex. Sản phẩm phụ của quá trình thu latex là mủ chén, chúng thực sự là phần latex còn sót lại trong chén, được thu gom vào những ngày sau khi thu hoạch latex cùng với một lượng nhỏ mủ cây. Thông thường, latex đóng góp khoảng 80% lượng cao su, trong khi lượng mủ chén và mủ cây chiếm khoảng 20%. Cao su nhiên thiên (NR) được chế biến thành latex hoặc cao su khô phụ thuộc vào ứng dụng của nó. Các sản phẩm được ngâm bao phủ cao su, bọt, tơ được sản xuất từ latex; trong khi các sản phẩm khác (ví dụ, lốp xe) được làm từ cao su khô. Các loại cao su thiên nhiên thương mại khác nhau được minh họa ở hình vẽ bên dưới.

Ảnh: Minh họa

Ở đây ta chú ý loại sản xuất truyền thống và loại cao su kỹ thuật (TSR) dạng khối. Loại truyền thống của NR gồm tờ xông khói (RSS), tờ sấy không khí nóng (ADS) và cao su crepe. Trong đó, RSS là phương pháp chế biến cao su loại latex cũ nhất và phổ biến. Chế biến RSS đi qua giai đoạn thu latex, giảm thành phần cao su khô (DRC) trong latex xuống khoảng 12.5%, đông tụ, ủ qua đêm, cán ngày hôm sau, và xông khói (sấy). Hoạt động cán cho phép khối đông tụ latex tạo thành tấm sau khi ủ. Quy trình tạo tấm thực tế là ép serum trong khối đông tụ ra ngoài và giảm bề dày của nó xuống khoảng 3.0 mm bằng cách cho phần đông tụ đi qua một chuỗi bốn trục cán phẳng và cuối cùng là các trục được tạo rãnh, làm cho hình dạng tấm cuối cùng có gờ. Gờ hỗ trợ việc tăng diện tích bề mặt và cải thiện tính năng sấy khô. RSS được sấy trong khói nhà (45 – 63oC), trong khi ADS được sấy trong buồng không khí nóng. Tấm sau khi sấy được kiểm tra ngoại quan và phân loại.

Gần đây, nhu cầu cho cao su kỹ thuật (TSR) dưới dạng khối ngày càng nhiều. Vì vậy, hầu hết các quốc gia sản xuất NR đang chuyển đổi chế biến cao su truyền thống thành TSR. Sản xuất cao su khối cơ bản là sự chuyển hóa cao su thô ướt thành dạng hạt bởi các kỹ thuật chế biến nhanh và liên tục. Cuối cùng, các mẫu hoặc hạt đã sấy khô được kết lại thành các khối cao su rắn. NR kỹ thuật ở dạng khối tạo thành từ latex là cao su chuẩn Malaysia màu sáng (SMR L), độ nhớt không đổi (SMR CV). Sản xuất SMR L cơ bản tập trung vào màu, với sự thêm vào sodium metabisulfite ở hàm lượng 0.04% thành phần cao su khô (DRC). Trong sản xuất SMR CV, cần thêm vào hydroxylamine sulfate trung tính ở 0.15% DRC. Các loại phổ biến của TSR được sản xuất từ mủ chén hoặc kết hợp với latex, dưới dạng cao su khối là SMR 10 và SMR 20; SMR GP, SMR 10 CV và SMR 20 CV.

Hiện tại Hóa Chất Mega Việt Nam đang cung cấp rất nhiều loại cao su thiên nhiên. Quý bạn đọc quan tâm vui lòng liên hệ đến số Hotline phía dưới.

Xin chân thành cảm ơn!

>>> Xem thêm các sản phẩm Cao su thiên nhiên mà chúng tôi cung cấp <<<< />pan>

Mọi thông tin vui lòng liên hệ:

Ban Biên tập Mega Việt Nam

Địa chỉ: Tầng 2-A2-IA20, KĐT Nam Thăng Long, đường Phạm Văn Đồng,

P.Đông Ngạc, Q. Bắc Từ Liêm, TP. Hà Nội, Việt Nam.

Email: contact@megavietnam.vn

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89098

Website: megavietnam.vn

Hotline: 1800.577.728; Zalo: 0971.023.523