TRANSPARENT WOOD - NEW ALTERNATIVE TO PLASTIC AND GLASS

Transparent wood has little impact on the environment and can contribute to reducing energy costs

GRAPHENE: THE SUPER MATERIAL FORMULATED FROM PLASTIC

COOLING PAINT

PLASTIC FOAM RECYCLING

FLEXIBLE GLASSES - INSPIRATION FROM SEASHELLS

TRANSPARENT WOOD - NEW ALTERNATIVE TO PLASTIC AND GLASS

A team at the Indian Institute of Technology (IIT) found that transparent wood has little impact on the environment and can contribute to reducing energy costs, Interesting Engineering reported on October 20. The new study was published in the journal Science of The Total Environment.

According to the United Nations Environment Program (UNEP), 400 million tons of plastic are produced annually, most of which is single-use plastic. Countries are making great strides in reducing this type of waste, such as plastic bags and straws. However, some items still need the characteristics of plastic.

Transparent wood is an alternative to such items and is popular for avoiding the harmful effects of petroleum-based plastic products. German scientist Siegfried Fink first produced fine wood in 1992, and over the past three decades, researchers have dramatically improved the material.

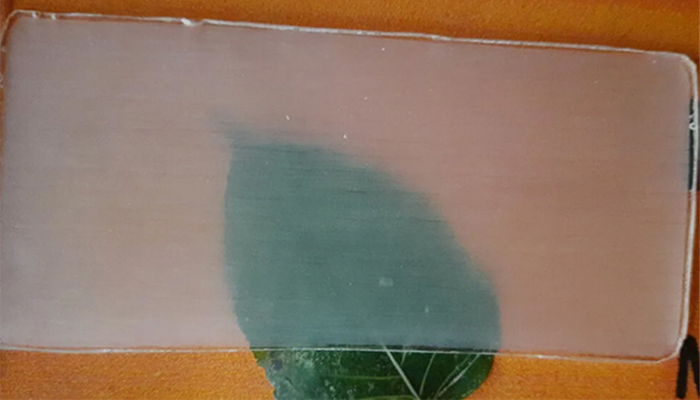

In the natural form, the wood is opaque. However, the scientists found that removing lignin, a natural biopolymer that gives structure to plant tissue could make wood transparent. To do so, the wood is soaked in a warm solution containing various chemicals such as sodium hydroxide, sodium sulfite, and sodium hypochlorite, and then boiled in a hydrogen peroxide solution.

This process will thoroughly remove the lignin and cause the wood to turn white. However, the space that once contained the lignin needs to be filled to keep the structure intact. This process is called permeation and is done using a resin such as epoxy or Poly methyl methacrylate (PMMA) with a temperature of 85 degrees Celsius.

The final product can be highly transparent and has shatterproof properties. More importantly, it is easier to biodegrade than glass or plastic. Although not yet commercialized, transparent wood is already used in many fields, from construction to energy storage, electronics manufacturing and packaging.

Researchers at IIT conducted a life cycle analysis (LCA) of transparent wood to determine the environmental impact of the manufacturing process and end-of-life (EOL). Research shows that using hydrogen peroxide to reduce lignin, and then using epoxy to penetrate, will be the most environmentally friendly.

This method reduces the risk of global warming by 24% and soil acidification by 15% compared with sodium chloride for lignin reduction and PMMA for percolation. When scaled up to apply to industrial production, the new method will reduce electricity consumption by 98.8%. The EOL analysis also shows that transparent wood reduces the ecological impact by about 107 times compared to polyethylene, paving the way for commercial adoption to replace petroleum-based materials.

>> Click HERE to read our UPDATED NEWS<<

Contact

MEGA VIETNAM

Office address: Floor 2-A2-IA20, Nam Thang Long Urban Area, Pham Van Dong Street,

Dong Ngac Ward, Bac Tu Liem District, Hanoi City, Vietnam

Email: contact@megavietnam.vn

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89 098

Website: megavietnam.vn

Hotline: 1800.577.728 Zalo: 0971.023.523