GRAPHENE: THE SUPER MATERIAL FORMULATED FROM PLASTIC

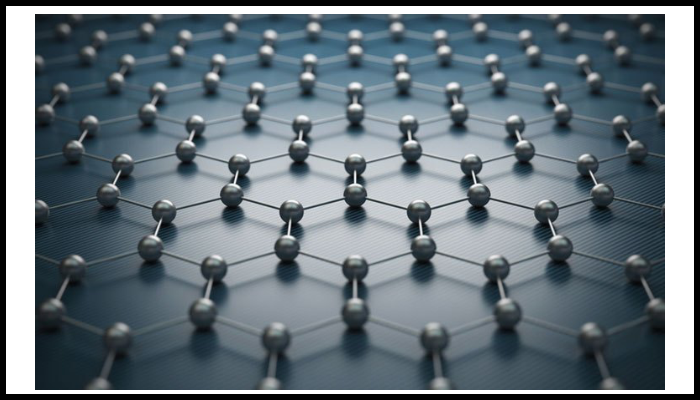

Graphene is called the super material of the future which is an allotrope of carbon consisting of a single layer of atoms arranged in a two-dimensional honeycomb lattice.

COOLING PAINT

PLASTIC FOAM RECYCLING

FLEXIBLE GLASSES - INSPIRATION FROM SEASHELLS

Eco-Friendly Plastic Using DNA From Salmon Sperm

GRAPHENE: THE SUPER MATERIAL FORMULATED FROM PLASTIC

Graphene is called the super material of the future which is an allotrope of carbon consisting of a single layer of atoms arranged in a two-dimensional honeycomb lattice.

Its durability has been proven to be 300 times more durable than steel and much more flexible than silicon, with good thermal conductivity, graphene is currently considered the ideal material for wearable devices. Some applications can be mentioned such as:

- Producing batteries

- Producing computer chips

- Smartphone components

- Energy cells

- Live tissue applications

Photo: Structure of Graphene the super material

>>> Click HERE for free construction advice <<<

To minimize plastic waste, the research team at Rice University (USA) has found a way to turn plastic waste into high-quality Graphene material. The team applied the Joule heating technique, which involves passing large electric currents through plastic materials. Under the right conditions, this high temperature can cause chemical changes and the formation of other new materials.

To make Graphene material, plastic waste is cut into small enough pieces. Usually, plastics are resistive, meaning they cannot conduct electricity. However, cutting into small pieces of about 50 micrometers can increase the plastic's electrical conductivity.

The team injects extremely high electrical current into the plastic to rapidly heat and chemically transform the plastic. High-quality graphene material is created using a combination of alternating current and direct current. Firstly, an alternating current is applied to the plastic for 8 seconds. The alternating current allows the resin to reach its initial temperature high enough to form graphene and facilitates rapid cooling of electrical impulses.

However, this alternating current produces only low-purity Graphene, at this point direct current is applied for 500 milliseconds. The direct current reaches a higher temperature than the alternating current. The material is gradually transformed and has properties similar to Graphene.

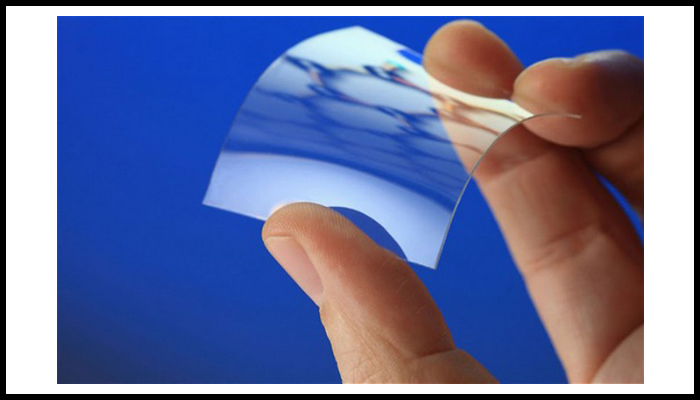

Transparent super material

Graphene is 200 times stronger than steel, a monolayer of Graphite which is a naturally occurring carbon-derived mineral. Normally, graphite is mined, then mechanically processed to split it into Graphene. However, this process is costly and can have an environmental impact.

The direct generation of graphene from plastic waste can reduce production costs and is widely used in research and construction, and can be combined with concrete, rubber, or asphalt to improve durability and efficiency. Also, graphene generated from the plastic can reduce pollution instead of graphene mined from graphite. The ability of this new type of graphene to biodegrade is in the research process, the team said. New graphene can break down within months, much faster than conventional resins.

>>> Click HERE for more updated news of Megavietnam<<<

Contact

MEGA VIETNAM

Office address: Floor 2-A2-IA20, Nam Thang Long Urban Area, Pham Van Dong Street,

Dong Ngac Ward, Bac Tu Liem District, Hanoi City, Vietnam

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89 098

Website: megavietnam.vn

Hotline: 1800.577.728 Zalo: 0971.023.523