THE ROLE OF ZINC OXIDE IN THE CERAMIC INDUSTRY

And one of the materials that are widely and commonly used in the Ceramic industry is zinc oxide (ZnO)

PROCESSING AND CLASSIFICATION OF NATURAL RUBBER

RUBBER ACCELERATOR MBT

BLOWING AGENT FOR RUBBER AND PLASTIC

INTRODUCTION TO RUBBER ACCELERATOR MBTS (DM)

THE ROLE OF ZINC OXIDE IN THE CERAMIC INDUSTRY

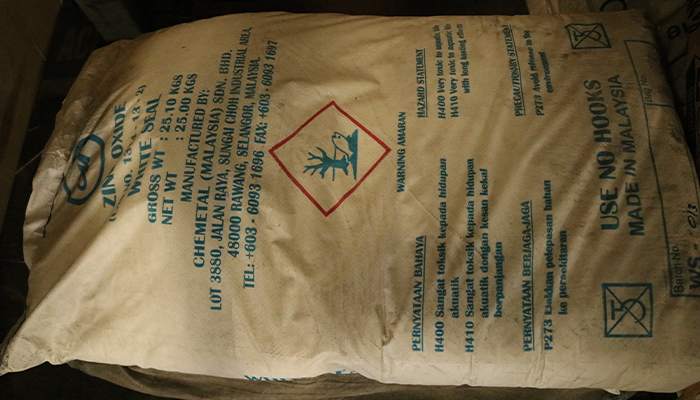

In the ceramic industry, each additive used in the manufacturing process has different uses, helping the product to have the desired properties. For example, there are substances that would reduce plasticity in plastics, there are substances that make glass, color, or blur. And one of the materials that are widely and commonly used in the Ceramic industry is zinc oxide (ZnO)

In which, Zinc oxide belongs to the group of fluxes. A substance that, when added, has the main effect of reducing the melting point of yeast.

Working mechanism:

Zinc oxide begins its flux function at about 1,000 °C. However, zinc oxide is easily reduced to metallic zinc by CO and H2 in the reducing furnace environment of a gas furnace (or an electric furnace with poor ventilation). Pure metallic zinc melts again at 419 °C, boils, and vaporizes at 907 °C. Low thermal expansion zinc oxide can be used in place of high thermal expansion fluxes to prevent enamel cracking. This is because zinc oxide partially replaces calcium oxide, it can prevent lead evaporation. Because too much calcium oxide will take up silicon dioxide and leave lead oxide volatile. Zinc's high density and its high density would reduce the shrinkage of enamel before burning.

>> Get advice on technical solutions during product construction <<

Note:

- Medium and high zinc oxide usage content, dull and crystallized enamel surface.

- The reaction of zinc oxide on colors is quite complex. It can have beneficial or harmful effects in blue, brown, green, pink colors and is not recommended with copper, iron, or chromium.

- In high concentrations, zinc oxide can be an opacifier (opaque white).

Currently, Mega Vietnam General Trading Company we are the leading supplier and distributor of Zinc Oxide Powder in Vietnam market with many products for applications such as manufacturing ceramics, rubber, pharmaceutical products. Products distributed by us ensure quality goods and stable sources, very competitive prices, suitable for the actual use needs of each customer.

>> Click for the best rubber chemicals on the market today <<

Contact

MEGA VIETNAM

Office address: Floor 2-A2-IA20, Nam Thang Long Urban Area, Pham Van Dong Street,

Dong Ngac Ward, Bac Tu Liem District, Hanoi City, Vietnam

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89 098

Website: megavietnam.vn

Hotline: 1800.577.728 Zalo: 0971.023.523