6 LOẠI HÓA CHẤT XÚC TIẾN CAO SU PHỔ BIẾN NHẤT HIỆN NAY

Trong quá trình sản xuất cao su, chất gia tốc lưu hóa, còn gọi là chất xúc tiến lưu hóa, là chất hữu cơ có tác dụng tăng tốc độ lưu hóa cao su. Được sử dụng với một lượng nhỏ, có khả năng làm giảm thời gian hay hạ nhiệt độ gia nhiệt, giảm tỷ lệ sử dụng chất lưu hóa và cải thiện chất lượng sản phẩm. Một số hóa chất phổ biến nhất được sử dụng hiện nay như: Xúc tiến lưu hóa MBT, MBTS, CBS, DPG, TMTD, ZDEC, ZMBT.

1. Xúc tiến lưu hóa MBT (Mercaptobenzothiazole)

- Tên khác: 2-mercaptobenzothiazole

2-benzothiazol-tiol

- Công thức:

- Tính chất: dạng bột hay hạt xốp, hạt vàng, vị đắng, mùi đặc trưng. Các sản phẩm thương mại hơi khác biệt nhau về tính chất.

- Tác dụng: Trong phụ gia ngành cao su, xúc tiến lưu hóa MBT có 3 tác dụng chính:

+ Tác dụng xúc tiến lưu hóa nhanh cho cao su tự nhiên, cao su tổng hợp và cao su latex kể từ nhiệt độ 120°C.

+ Tác dụng tăng hoạt mạnh cho chất gia tốc Baz, như DPG nhóm guanidine chẳng hạn, trở thành hỗn hợp xúc tiến lưu hóa bác cực nhanh.

+ Tác dụng hóa dẻo mềm cao su thiên nhiên theo tiến trình hóa học.

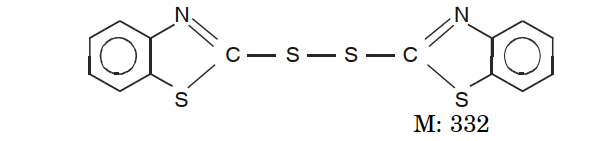

2. Xúc tiến lưu hóa MBTS (Disulfur Benzothiazyl)

- Tên khác: 2-Benzothiazolyl disulfide,

Disulfur de benzothiazyl,

Dibenzothiazyl disulfide,

2,2'-dithio-bis-benzothiazole.

- Công thức:

- Tính chất: dạng bột hoặc hạt nhỏ xốp màu vàng nhạt hơi trắng (trắng hơi vàng), không mùi, không độc. Tỷ trọng d=1,5. T°nc trung bình bằng 170°C. Tan trong benzene, chloroform, acetone, ether. Không tan trong nước, ét xăng.

- Tác dụng: Trong phụ gia ngành cao su, xúc tiến lưu hóa MBTS có 5 tác dụng chính sau:

+ Lưu hóa gia tốc nhanh cho các hỗn hợp cao su tự nhiên và cao su tổng hợp ở nhiệt độ 140°C. Dưới nhiệt độ này (120°C) có tác dụng gia tốc trung bình, nhưng có tính an toàn sử dụng rất tốt cho các hỗn hợp cán luyện, định hình, tức là khó lưu hóa sớm hơn MBT.

+ Tăng hoạt hoặc được tăng hoạt bởi các gia tốc nhóm guanidine, thiuram, dithiocarbamate vaâ aldehyde-amine.

+ Phụ trợ lưu hóa cao su butyl với chất lưu hóa dioxime quinone hay quinone dioxime dibenzoate.

+ Hóa dẻo cao su thiên nhiên theo tiến trình hóa học, nhưng tác dụng kém hơn xúc tiến lưu hóa MBT.

3. Xúc tiến lưu hóa CBS

- Tên hóa học: 2-benzothiazole sulfonamide

- Công thức: C13H16N2S2

- Tính chất: Bột màu trắng xám, nhiệt độ nóng chảy min 98.0oC

+ Là chất xúc tiến lưu hóa có thời gian chảy ban đầu dài, khả năng chống tự lưu cao nhưng cho thời gian lưu hóa ngắn, mâm lưu hóa rộng. Tăng cường mật độ liên kết trong quá trình lưu hóa giúp cải thiện ứng suất kéo và độ bền nén của sản phẩm.

+ Hạn chế vấn đề ngã màu, phun sương sau lưu hóa, đóng vai trò như chất phòng lão trong quá trình lưu hóa.

- Tác dụng:

+ Được sử dụng là chất xúc tiến lưu hóa thứ cấp cùng chất trợ lưu hóa ZnO, acid stearic để tăng cường hiệu quả lưu hóa của TMTD, TMTM, ZDMC, DPG, MBT và MBTS…

+ Xúc tiến lưu hóa CBS được sử dụng như là chất xúc tiến cho hệ lưu hóa ít lưu huỳnh khi kết hợp với xúc tiến họ thiuram và dithiocarbamate, kéo dài thời gian chảy hỗn hợp của hệ xúc tiến lưu hóa này.

4. Xúc tiến lưu hóa DPG

- Tính chất: Bột màu trắng mịn. T°nc 145°C, d = 1,13 - 1,19. Không mùi, tan trong benzene, toluene, chloroform, acetone, cồn, ether. Tan ít trong nước, không tan trong ét - xăng. Có vị hơi đắng.

- Công dụng: Trong phụ gia ngành cao su, xúc tiến lưu hóa DPG có 4 công dụng:

+ Xúc tiến lưu hóa trung bình, tính baz, nhóm guanidine, ở nhiệt độ tác dụng trên 140°C cho cao su thiên nhiên và cao su tổng hợp.

+ Tăng hoạt hay phụ trợ mạnh cho chất xúc tiến nhóm thiazole, thiazoline hay thiuram; nhất là nhóm thiazole acid, phối hợp trở thành một hỗn hợp có tốc độ gia tốc bán cực nhanh cho lưu hóa cao su thiên nhiên và cao su tổng hợp butadiene-styrene. Khi đó hiện tượng “chết trên máy” của hỗn hợp cao su dễ xảy ra. Với điều kiện hiện nay, có thể phối hợp xúc tiến lưu hóa DPG với disulfur benzothiazyl (accelerateur DM) an toàn hơn.

+ Hóa dẻo rất hiệu quả cho cao su tổng hợp chlorobutadiene, nhưng cũng vừa có tác dụng gia tốc lưu hóa chậm và cũng như đa số baz hữu cơ, DPG có tác dụng hóa dẻo vái polysulfur alken như Thiokol A, Thiokol AZ. Để duy trì hiệu quả hóa dẻo này mặc dù có chất độn như khói carbon hay oxit kẽm, ta thêm disulfur thiuram.

+ Hấp thụ nhiệt đông đặc latex, tức là giúp cho latex đông lại khi hấp thụ nhiệt nóng.

5. Xúc tiến lưu hóa ZDEC

- Tính chất: Bột màu trắng (hạt). Mật độ a1.41. Hòa tan trong 1% sodium hydroxide, carbon disulfide, Benzene, Chloroform, hơi hòa tan trong rượu, không hòa tan trong xăng.

- Tên khác: Ethyl zimate

- Ứng dụng: Xúc tiến lưu hóa ZDEC chủ yếu được sử dụng trong sản xuất các sản phẩm y tế, băng và Tự-chữa sản phẩm. Nó là 0.5-1 phần trong khô cao su.

6. Xúc tiến lưu hóa ZMBT

- Tên hóa học: Zinc-2-Mercaptobenzothiazole

- Tính chất:

+ Dạng bột màu trắng

+ Điểm nóng chảy ℃: ≥ 200

+ Hàm lượng kẽm: 15-18%

+ Hàm lương MBT tự do 14-18%

- Ứng dụng: Chất xúc tiến lưu hóa cho cao su tự nhiên, cao su latex và cao su tổng hợp

Để tìm mua sản phẩm chất lượng ổn định, giá cả hợp lý vui lòng liên hệ với chúng tôi. Hiện Mega Việt Nam chúng tôi cung cấp và đang triển khai rộng rãi chất xúc tiến lưu hóa tại thị trường trong nước cho sản xuất cao su, từ đó tự tin đáp ứng được mọi nhu cầu của Quý Khách hàng.

>> Xem thêm các loại hóa chất ngành cao su tốt nhất hiện nay trên thị trường <<

Mọi thông tin vui lòng liên hệ:

Ban Biên tập Mega Việt Nam

Địa chỉ: Tầng 2-A2-IA20, KĐT Nam Thăng Long, đường Phạm Văn Đồng,

P. Đông Ngạc, Q. Bắc Từ Liêm, TP. Hà Nội, Việt Nam.

Email: contact@megavietnam.vn

Tel: (+84) 24 375 89089; Fax: (+84) 24 375 89098

Website: megavietnam.vn

Hotline: 1800.577.728; Zalo: 0971.023.523